Many of the products we use every day started out as nothing more than a huge piece of metal. Sheet metal fabricators use a wide variety of means, which can include welding, joining, and buffing. They use whatever type of material you want and your physical requirements to create the product you want/need efficiently and cost effectively.

What is Metal Fabrication?

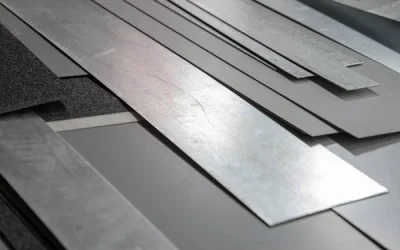

To begin with, it is helpful to know that one of the most commonly used types of raw materials is metal. Basically, metal fabrication is the process of shaping and joining the metal by deforming it. You can find sheet metal in thicknesses between .006 and .25 inches. Thinner than that is foil and any thicker and it is referred to as a plate.

How Does Metal Fabrication Work?

There are times that sheet metal fabrication involves a variety of processes, including:

*Cutting metal by way of the use of aviation snips, which are still the preferred method. This can also be accomplished using power scissors quicker and more easily.

*Pieces of metal can also be removed through machining, either by use of a lathe.

*A punch and die tool uses pressure to make a hole in the metal in many different shapes and sizes.

*Stamping is a process that makes a part of the metal raise in a design, but does not cut through.

Fabrication Materials

One of the most important aspects of the process is the choice of material. Not only will it affect the budget, but more importantly the integrity of the entire project. While galvanized sheet metal is generally the first choice, you could also pick from black iron sheet, aluminum sheet, or stainless steel sheet. If you are looking for practical solutions from a welding company who will provide you will 24/7 service, contact Exotic Welding.